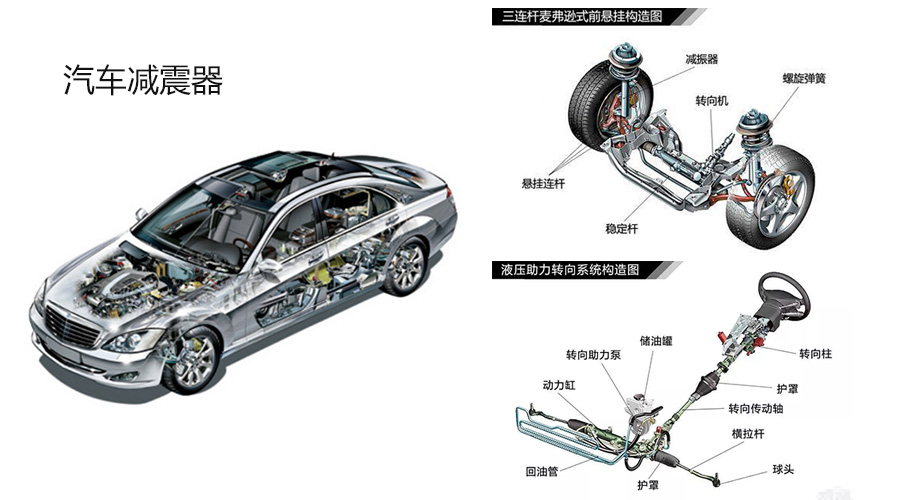

減震器的用途:The function of shock absorbers:

減震器,是用來(lái)抑制彈簧吸震后反彈時(shí)的震蕩及來(lái)自路面的沖擊,為加速車(chē)架與車(chē)身振動(dòng)的衰減,以改善汽車(chē)的行駛平順性(舒適性),在大多數(shù)汽車(chē)的懸架系統(tǒng)及轉(zhuǎn)向系統(tǒng)內(nèi)部裝有減震器。

The shock absorber, is used to suppress the shock when the spring rebounds and the shock from the road surface, to accelerate the attenuation of the frame and the body vibration, to improve the ride comfort (comfort) of the car, in the suspension of most cars. Shock absorbers are installed inside the system and steering system.

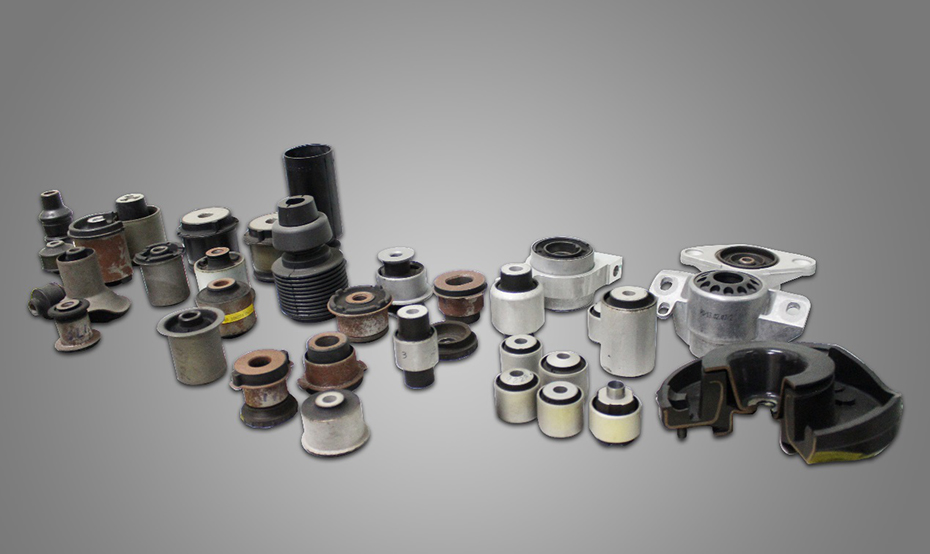

汽車(chē)減震器的生產(chǎn)工藝 Car suspension production process:

汽車(chē)減震器的制作工藝比較復(fù)雜,我們以減震器襯套為例,講解襯套的工藝流程,并說(shuō)明哪些工藝流程會(huì)用到我們的設(shè)備。

The manufacturing process of automobile shock absorber is quite complicated. Taking the bushing as an example, we explain the technological process of the bushing and explain which technological process will be used in our equipment.

工藝流程: Process:

骨架→前處理(磷化、噴砂、清洗)→噴膠→橡膠注射硫化→修邊→縮外徑→檢測(cè)外徑尺寸→剛性測(cè)試→涂油→包裝

Skeleton pretreatment (phosphating, sandblasting, cleaning) → spray glue → glue injection vulcanization → trimming → calibrate outer diameter → test outer diameter size → rigidity test → oil painting → packaging

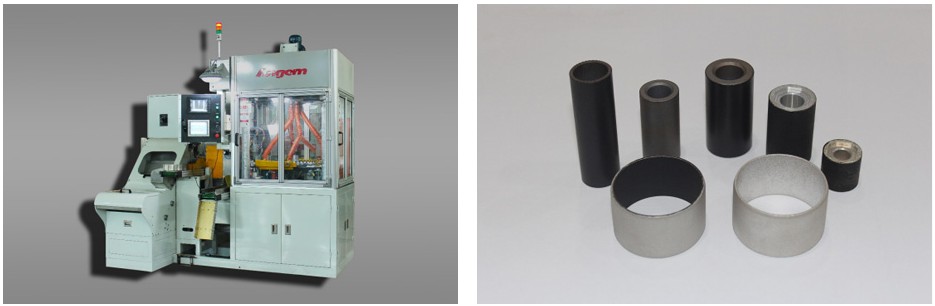

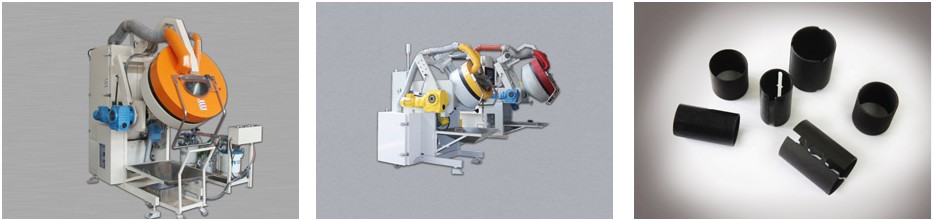

以下工序會(huì)用到我們的設(shè)備:The following process will use our equipment

前處理設(shè)備:自動(dòng)磷化線 Pretreatment equipment: Automatic Phosphating Line

噴膠:自動(dòng)噴膠機(jī) Glue spraying: Automatic Glue Spraying Machine

自動(dòng)滾膠機(jī) Automatic Roller Gumming Machine

自動(dòng)滾噴機(jī) Automatic Rotating Roller Spray Machine

縮外徑:自動(dòng)縮徑機(jī) Outer-diameter crimping: Automatic Crimping Machine

檢測(cè)外徑、剛性測(cè)試:多工位后制程專(zhuān)機(jī)

Outside diameter checking and rigidity test: multi-station post-process special machine

行業(yè)痛點(diǎn):Industry pain points:

1、人工成本高,膠粘劑利用率低;

High labor cost and low utilization rate of adhesive

2、手工噴涂膜厚不均勻;

Uneven thickness of manual spraying film

3、容易出現(xiàn)漏噴漏涂現(xiàn)象,導(dǎo)致產(chǎn)品批量報(bào)廢;

It is easy to miss coating one or some products, leading the whole batch scrapping

4、傳統(tǒng)方式涂膠及晾干占地面積大,車(chē)間成本高;

The traditional way of gluing and drying covers a large area and the cost of the workshop is high

5、化學(xué)溶劑、粉塵污染對(duì)車(chē)間以及人體健康的影響。

The chemical solvent and dust pollution on the workshop hurt human health.

產(chǎn)品要求:Product requirement:

1、不同結(jié)構(gòu)及大小的產(chǎn)品通用性;

Versatility of products with different structures and sizes

2、粘合劑膜厚均勻,硫化后粘結(jié)強(qiáng)度高、不脫膠;

The film thickness of the adhesive is even, and after vulcanization, the bonding strength is high, not degumming

3、產(chǎn)品日產(chǎn)量要求效率高。

The daily output of products requires high efficiency.

我們的優(yōu)勢(shì): Our advantages:

1、自動(dòng)化程度高、操作更安全;

High degree of automation and safer operation;

2、生產(chǎn)節(jié)拍短、效率高,適合產(chǎn)品大規(guī)模生產(chǎn);

Short production cycle, high efficiency, suitable for mass production;

3、膠漿利用率提高、節(jié)省成本;

Improve the adhesive utilization rate and save costs;

4、膜厚均勻、質(zhì)量更穩(wěn)定;

Even film thickness and more stable quality;

5、占地面積小,能耗低;

Small floor area and low energy consumption;

6、精準(zhǔn)流量監(jiān)控、影像檢測(cè)、色標(biāo)檢測(cè)等防錯(cuò),堵槍自動(dòng)報(bào)警,確保產(chǎn)品質(zhì)量;

Accurate flow monitoring, image detection, color standard detection and other error prevention, blocking gun automatic alarm, to ensure the product quality;

7、全封閉式涂裝,粉塵經(jīng)過(guò)精密過(guò)濾,確保車(chē)間無(wú)污染。

Fully enclosed coating, dust filtered by precision filtration, to ensure no pollution workshop.

其他服務(wù):Other services:

1、可免費(fèi)提供打樣;

Provide sample coating for free;

2、提供產(chǎn)品針對(duì)性噴涂設(shè)備研發(fā);

Provide spraying equipment research and development for special product;

3、長(zhǎng)期提供技術(shù)支持和上門(mén)解決技術(shù)難題;

Provide long-term technical support and solve technical problems on site;

4、提供噴涂工藝及設(shè)備操作培訓(xùn)。

Provide spraying process and equipment operation training.

全國(guó)服務(wù)熱線

全國(guó)服務(wù)熱線